Cnc Waterjet Cutting Machine

| Specification | Details |

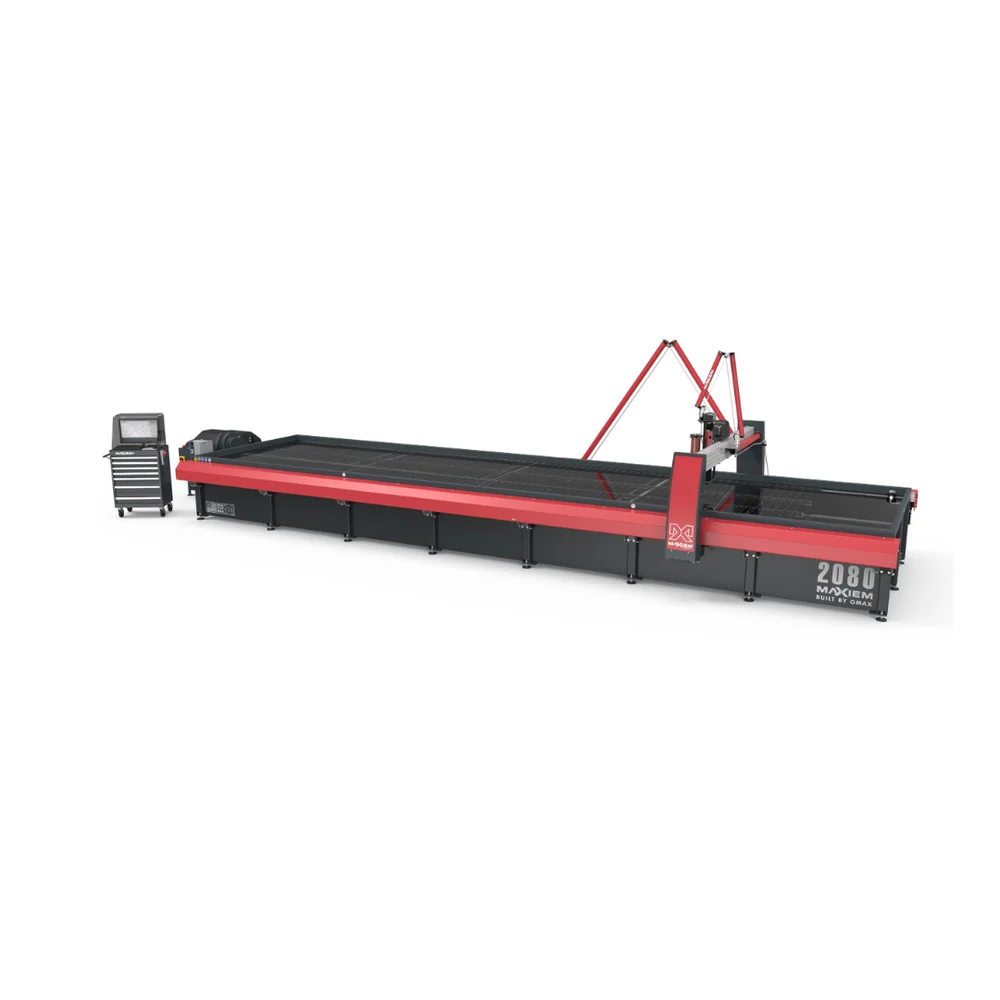

| Machine Type | CNC Waterjet Cutting Machine |

| Cutting Technology | High Pressure Waterjet |

| Max Cutting Thickness | Up to 150 mm (material dependent) |

| Working Table Size | Customizable |

| Cutting Accuracy | ±0.1 mm |

| Control System | Advanced CNC Controller |

| Supported Materials | Metal, Stone, Glass, Rubber, Plastic |

| Pump Pressure | 3000–6000 Bar |

| Power Requirement | Industrial 3 Phase |

| Applications | Industrial & Fabrication Use |

Product Details

What is a CNC Waterjet Cutting Machine?

A CNC Waterjet Cutting Machine is an advanced industrial machine that uses ultra-high pressure water to cut various materials. Since it doesn't generate heat, the material's structure and quality remain completely intact. This technology is especially ideal for industries where precision and a clean finish are essential.CNC Waterjet Cutting Machine Price Factors

The price of a CNC Waterjet Cutting Machine depends on several factors such as machine size, pump pressure capacity, CNC controller type, and level of automation. Machines for heavy-duty industrial use are more expensive, while basic models are available at a more moderate price. Custom table size and additional features also influence the price.

Main Features & Benefits of the Machine

The biggest advantage of this machine is its ability to cut almost any type of material – metal sheets, granite, marble, glass, rubber, and composites. The CNC system ensures repeatable accuracy, which is very helpful in mass production. Waterjet cutting produces burr-free edges, reducing post-processing costs.

Industrial Applications

CNC Waterjet Cutting Machines are used in fabrication units, the automotive industry, aerospace parts manufacturing, stone processing, and custom metal design work. This machine is suitable for both small workshops and large-scale manufacturing units.Why Choose a CNC Waterjet Cutting Machine?

If you want precision cutting, low maintenance, and long-term reliable performance, a CNC Waterjet Cutting Machine is a smart investment. Its versatility and accuracy take your production quality to the next level, improving overall business efficiency.

About Techno Laser Engineering

| Company Name | Techno Laser Engineering |