Heating Element Manufacturers in India | Industrial Heating Element

| Specification | Details |

| Product Category | Industrial/Commercial Electric Heating Elements |

| Manufacturer Capability | Standard models + Custom fabrication |

| Element Types | Tubular, Immersion, Finned, Duct/Air Heater, Cartridge/Coil |

| Power Range | 0.5kW to 30kW (application based) |

| Voltage Options | 110–120V / 220–240V / 380–415V |

| Sheath Materials | SS 304 / SS 316 / SS 321 / Incoloy (use-case dependent) |

| Diameter Options | 6.5mm / 8mm / 10mm / 12mm (custom possible) |

| Mounting Options | Threaded, Flange, Clamp, Brackets |

| Temperature Capability | Up to 750°C (conditions & design dependent) |

| Control Compatibility | Thermostat / PID / Thermocouple support |

Product Details

Why is choosing Heating Element Manufacturers in India important?

In today's industrial and commercial setups, heating elements are an essential component—whether you're heating water, air, oil, or maintaining the temperature in a process vessel. Therefore, when people search for heating element manufacturers in India, their main intention is: “I need a reliable manufacturer who can provide quality heating elements with the correct specifications and ensure long-term performance.”

India has a strong manufacturing network, so you can find both standard models and custom fabrication based on your requirements. However, the selection shouldn't be based solely on price. If a heating element is made with cheap materials or the wrong watt density, it increases the risk of frequent failures, uneven heating, electricity wastage, and downtime. A good manufacturer understands your application and suggests the best type of element, the safest material, and the most suitable mounting/design.

If you are running multiple plants, making bulk purchases, or operating a continuous production line, consistent quality and repeatability become even more crucial. In this case, the manufacturer's testing process, workmanship, and support system directly impact your overall cost.

Manufacturer's Product Range – What types of heating elements are commonly manufactured?

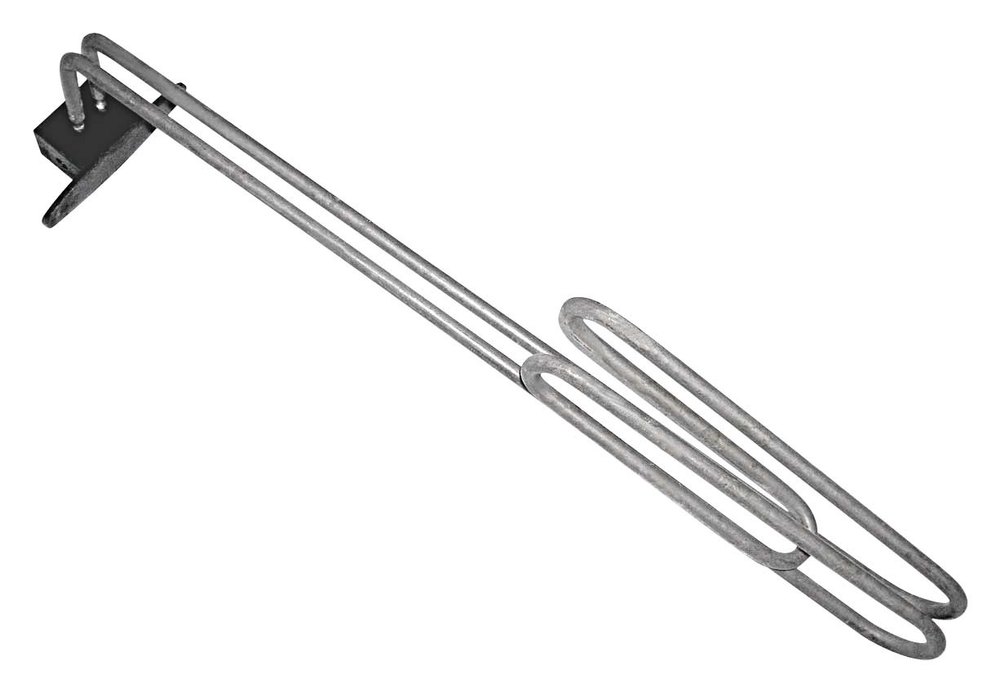

Heating element manufacturers in India usually cover a broad product range to fulfill the needs of different industries. The most common category is tubular heating elements. These are versatile and can be manufactured in straight, U-shape, W-shape, ring/coil, or custom bending configurations. Tubular elements are used in water tanks, ovens, hot plates, mold heating, packaging machines, heaters, and process equipment.

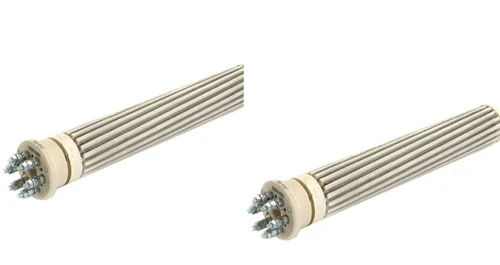

Immersion heaters are widely used for industrial water heating. They are installed in storage tanks, boilers, geysers, cleaning tanks, plating tanks, and process vessels. Immersion heaters come with threaded fittings or flange mounting. Flange type is heavy-duty and suitable for high kW requirements.

In air heating applications, finned heating elements and duct heaters are popular. Fins increase the surface area, making heat transfer in the airflow more efficient. These are used in hot air blowers, dryers, HVAC systems, shrink tunnels, and industrial drying chambers. In air heating, selecting the element according to the design airflow is crucial; otherwise, the element can overheat.

For machine-specific heating, cartridge heaters and coil heaters are manufactured, which are used in molds, dies, sealing jaws, hot runner parts, and compact heating zones. These heaters can provide high heat density, so accurate dimensions and proper insulation are important.

Material Selection and Specification – This determines life and safety

The performance of a heating element is based on the material, watt density, and insulation. In India, manufacturers generally offer sheath materials such as SS 304, SS 316, SS 321, and Incoloy.

- SS 304: Cost-effective in normal water/standard conditions.

- SS 316: Better corrosion resistance, recommended for hard water or humid environments.

- SS 321: Used in some cases for higher temperature stability.

- Incoloy: Premium choice for high temperature, harsh environments, and long life.

Besides this, the element's diameter, length, bending radius, terminal type, and mounting are also part of the specifications. If the mounting is mismatched (thread/flange), it can create leakage, vibration, loose fitting, and safety risks. In industrial use, earthing provision and proper terminal insulation are a must.

If you require temperature control, inform the manufacturer beforehand whether you are using a thermostat, PID controller, or thermocouple. This allows the element design and termination to be planned accordingly.

Quality Checks and Testing – What should the manufacturer follow?

A reliable manufacturer not only manufactures the element but also follows testing and inspection before dispatch. You can confirm these quality points at the time of inquiry/ordering:

- Insulation Resistance (IR) test: Reduces the risk of leakage current.

- Continuity test: Avoids coil breakage or internal faults.

- Dimensional accuracy: Ensures the element fits exactly, with no forcing/bending on-site.

- Termination sealing: Reduces moisture entry and short-circuit risk.

- Welding/End sealing finish: Flange/ends should be leak-proof and strong.

Material traceability (where possible): useful in critical applications.

The same level of testing is not mandatory for every application, but basic tests improve reliability in commercial/industrial use. If you are purchasing in bulk, a sample approval process is best practice—approve 1-2 units first, then the full lot.

Practical Method for Shortlisting Manufacturers (Buyer's Guide)

There are many options in India, so to choose the best manufacturer, focus on these points:

1) Application Understanding

Does the manufacturer recommend elements based on your use case? If they are only providing a generic quotation without asking questions, the risk increases.

2) Custom Capability

If you provide drawings, samples, or exact dimensions, can they build it exactly as specified? Custom bending and mounting accuracy are important in industrial setups.

3) Delivery & Repeatability

If you require repeat orders, the manufacturer's process should be consistent—the same output with the same specifications.

4) After-Sales Support

Whether replacement support, installation guidance, and troubleshooting help are available is crucial for a long-term relationship.

5) Pricing Transparency

The price breakdown (material, kW, mounting, customization) should be clear. The cheapest option is not always the best, as downtime and frequent replacements can be more costly in the long run.

What details should you provide for a quote?

- For a fast and accurate quotation, share these details:

- Medium: water/air/oil/process liquid

- Power: kW rating + voltage

- Size: length/diameter/shape

- Mounting: thread/flange (standard details)

- Operating temperature + hours/day

- Control: thermostat/PID/thermocouple

- Quantity + delivery timeline

About Rexco Industries India

| Company Name | Rexco Industries India |

.webp)